The progressive cavity pump

for an infinite number of applications

Pumps low-viscosity to high-viscosity media at up to 100 000 mPas

Virtually all media, from low-viscosity to high-viscosity and pasty, media that is sensitive to shearing and even media containing solids can be pumped with the VISCOPOWER. And the pump can be used in all sectors such as industry, chemicals, hygienic, pharmaceuticals and cosmetics. Even media that is not capable of flowing can be pumped with ease when the pump is combined with the FLUX VISCOFLUX lite and VISCOFLUX mobile S drum-emptying systems.

FLUX products are developed and certified for use around the globe. They meet the most exacting of requirements and safety standards. Whether food, pharmaceuticals or industry – or for hygienic or hazardous areas: there are pump versions suited to every use.

Power is in the detail

Power is in the detail

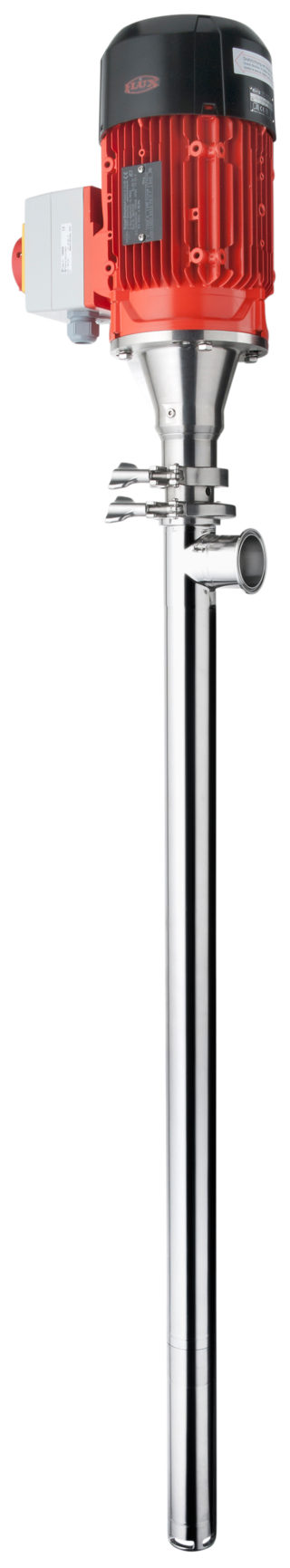

Motor

VISCOPOWER F 570 and F 580 can be run with many drive motors; be it commutator motors, three-phase motors, compressed air motors or brushless motors.

Bayonet fitting

Thanks to the bayonet fitting on the motor flange version, the pump can be easily hung on the motor and the screws can then be tightened without the pump having to be stopped.

Motor connection

Clamp connection allows the pump to be disassembled quickly, easily and without special tools.

Clamp connection

Eith the standardised clamp connection on the discharge, all kinds of hose connections, outlet fittings, flowmeters, bypass valves etc. can be easily connected using clamp adapters.

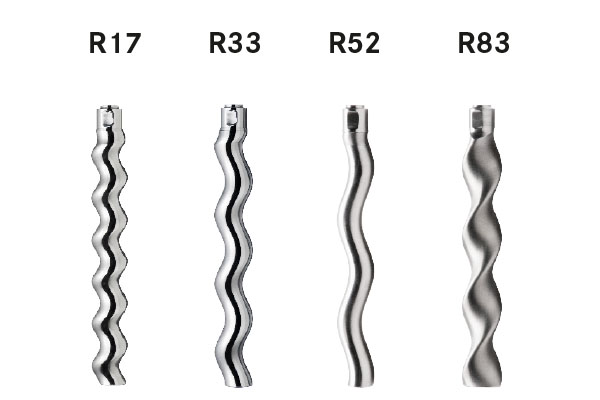

Rotor

With four different rotor geometries, the VISCOPOWER has the right solution for every requirement. No matter whether you need max. pump capacity, the delivery head or a low pump capacity for more accurate metering, one of the four geometries is sure to provide the ideal solution while keeping the same pump tube diameter.

Motor

VISCOPOWER F 570 and F 580 can be run with many drive motors; be it commutator motors, three-phase motors, compressed air motors or brushless motors.

Bayonet fitting

Thanks to the bayonet fitting on the motor flange version, the pump can be easily hung on the motor and the screws can then be tightened without the pump having to be stopped.

Clamp connection allows the pump to be disassembled quickly, easily and without special tools.

Eith the standardised clamp connection on the discharge, all kinds of hose connections, outlet fittings, flowmeters, bypass valves etc. can be easily connected using clamp adapters.

With four different rotor geometries, the VISCOPOWER has the right solution for every requirement. No matter whether you need max. pump capacity, the delivery head or a low pump capacity for more accurate metering, one of the four geometries is sure to provide the ideal solution while keeping the same pump tube diameter.

Properties and design

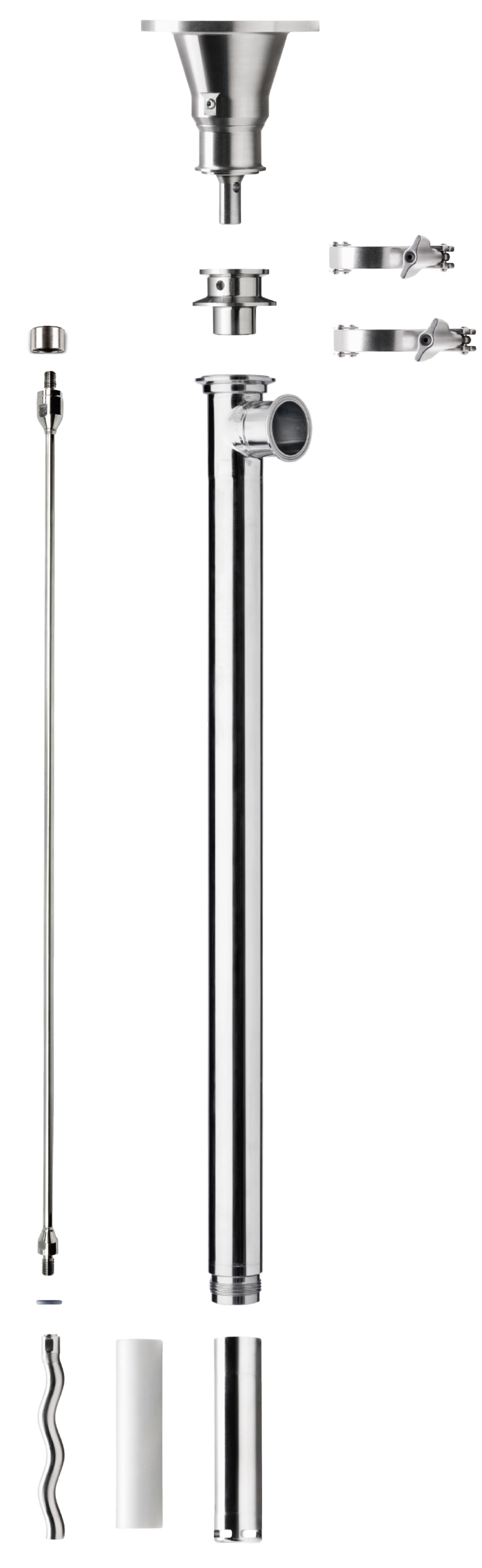

Modular, flexible and easy to disassemble the VISCOPOWER progressive cavity pumps

Disassembled for cleaning in 30 seconds

Industrial application

Production of fertiliser

Low-viscosity, high-viscosity, pasty, viscous or highly flammable – the requirements faced in industrial applications are hugely varied. Thanks to its modular design, the VISCOPOWER can be perfectly matched to even the most demanding pumping job. Common industrial applications for the VISCOPOWER include filling and decanting oils, lubricants, paints, resins, hardeners, glues and much more.

Gallery – for a large view please click on the image

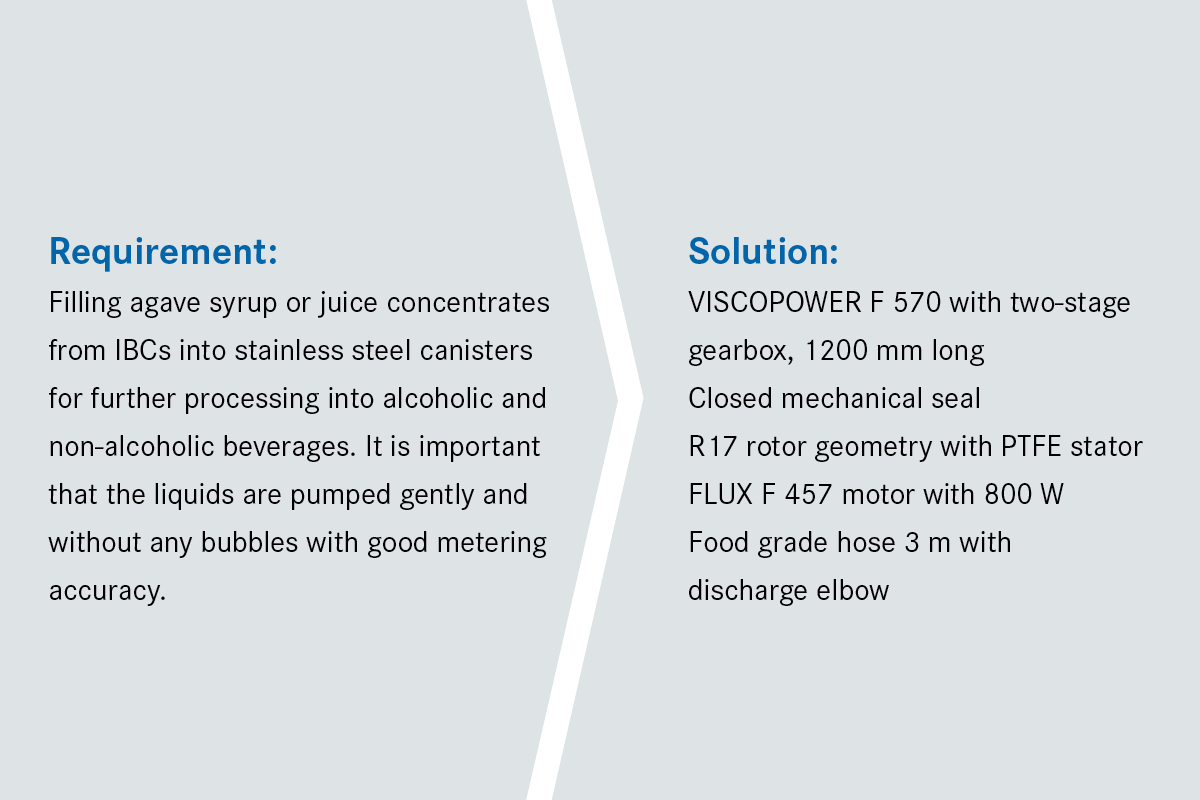

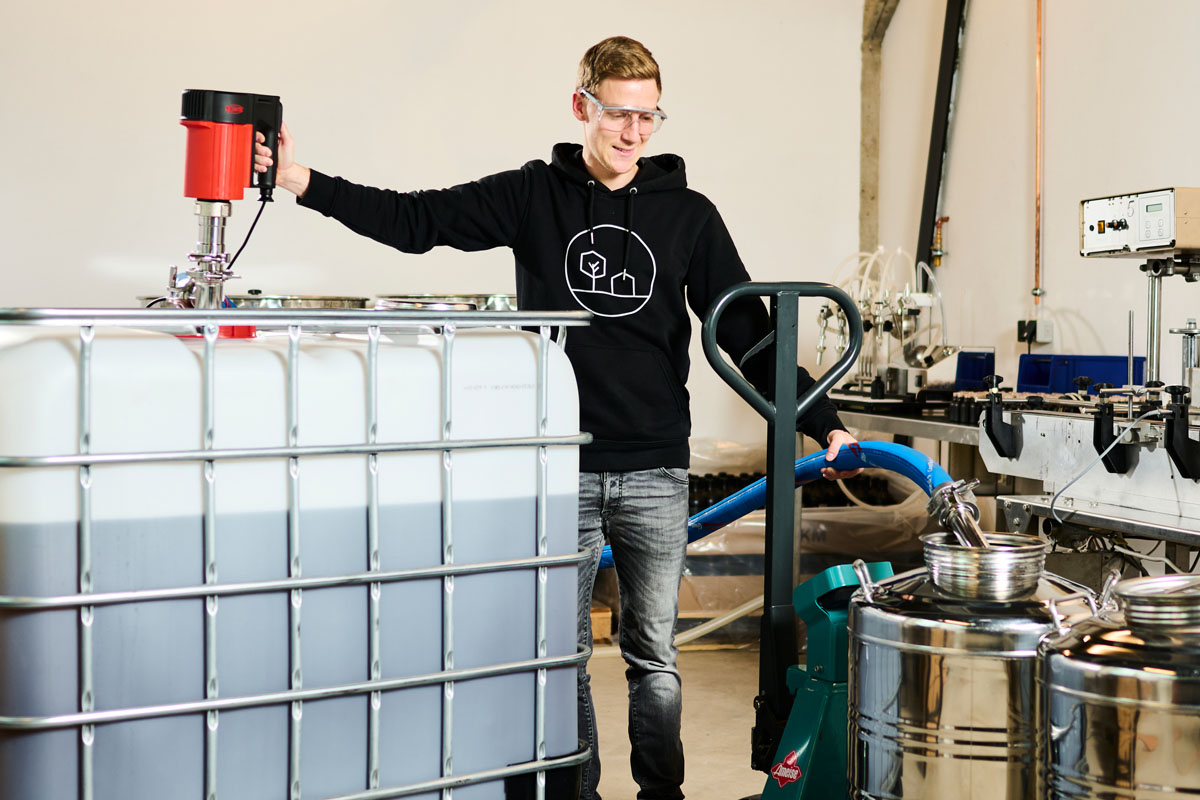

Hygienic application

Beverage production "HEIMAT DISTILLERS"

The VISCOPOWER makes light work of the stringent requirements applicable in the hygiene sector – thanks to its design with minimal dead space, the use of a closed mechanical seal and electropolished surfaces. It satisfies the EU standard (EC) 1935/2004 and (EU) 10/2011, FDA and 3A standards as well as the ATEX directives. Typical areas of use in the hygiene sector include Vaseline, wool fat, creams, tomato purée, juice concentrates, honey and much more.

Gallery – for a large view please click on the image

Beverage production “Rothaus”

Gentle and hygienic conveying is crucial in the production of mixed drinks based on natural fruit juice concentrates. Our progressing cavity pump in a gearbox design ensures even pumping - ideal for viscous media with high hygiene and cleanability requirements. The pump can be dismantled and cleaned in a few simple steps - for short downtimes, reliable processes and quick changes between different media.

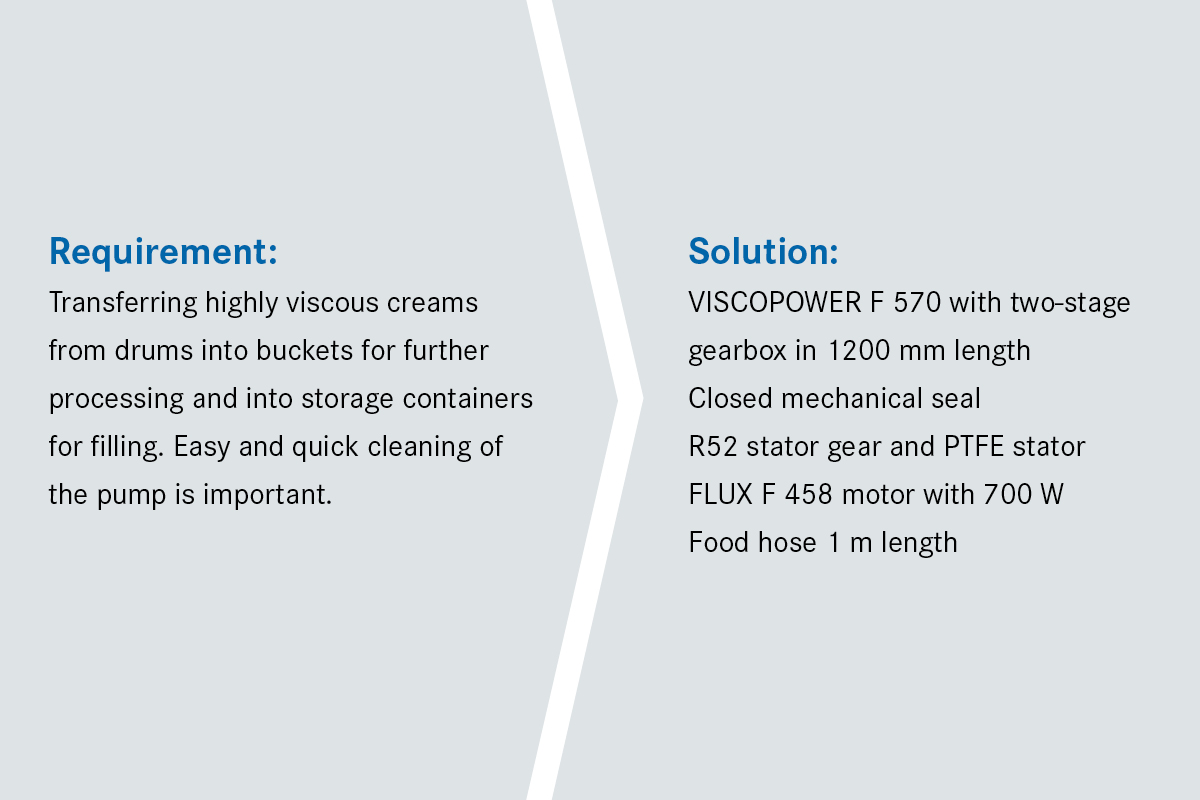

Application Pharma & Cosmetics

Ointment production "GW Cosmetics"

The VISCOPOWER is ideally suited for use in the pharmaceutical & cosmetics sector. It complies with EU Regulation (EC) 1935/2004 and (EU) 10/2011, FDA and 3A standards as well as ATEX directives. In addition, all dead spaces have been minimized in the design to prevent media build-up or carryover. Typical applications in pharma & cosmetics are Vaseline, wool grease, creams, ointments and many more.

Gallery – for a large view please click on the image

Pure Power made in Germany!

For over 70 years FLUX has been producing pumps, motors and accessories exclusively in Germany. With its own production, welding shop, motor winding shop, plastic injection molding shop and assembly in Maulbronn, Swabia, FLUX can justifiably claim to produce 100% MADE IN GERMANY. Low staff turnover, a family atmosphere, employees with decades of experience and the continuous training of junior staff are the recipe for success for FLUX's unparalleled product quality.